Model:Single RH120-RH120-RH90/RH130/26+RH130/26/RH95-RH85/Parallel Twin Screw RH-95(Product Width(mm) :2000-3000)

Production Capacity: 1500 kg/h~4000kg/h

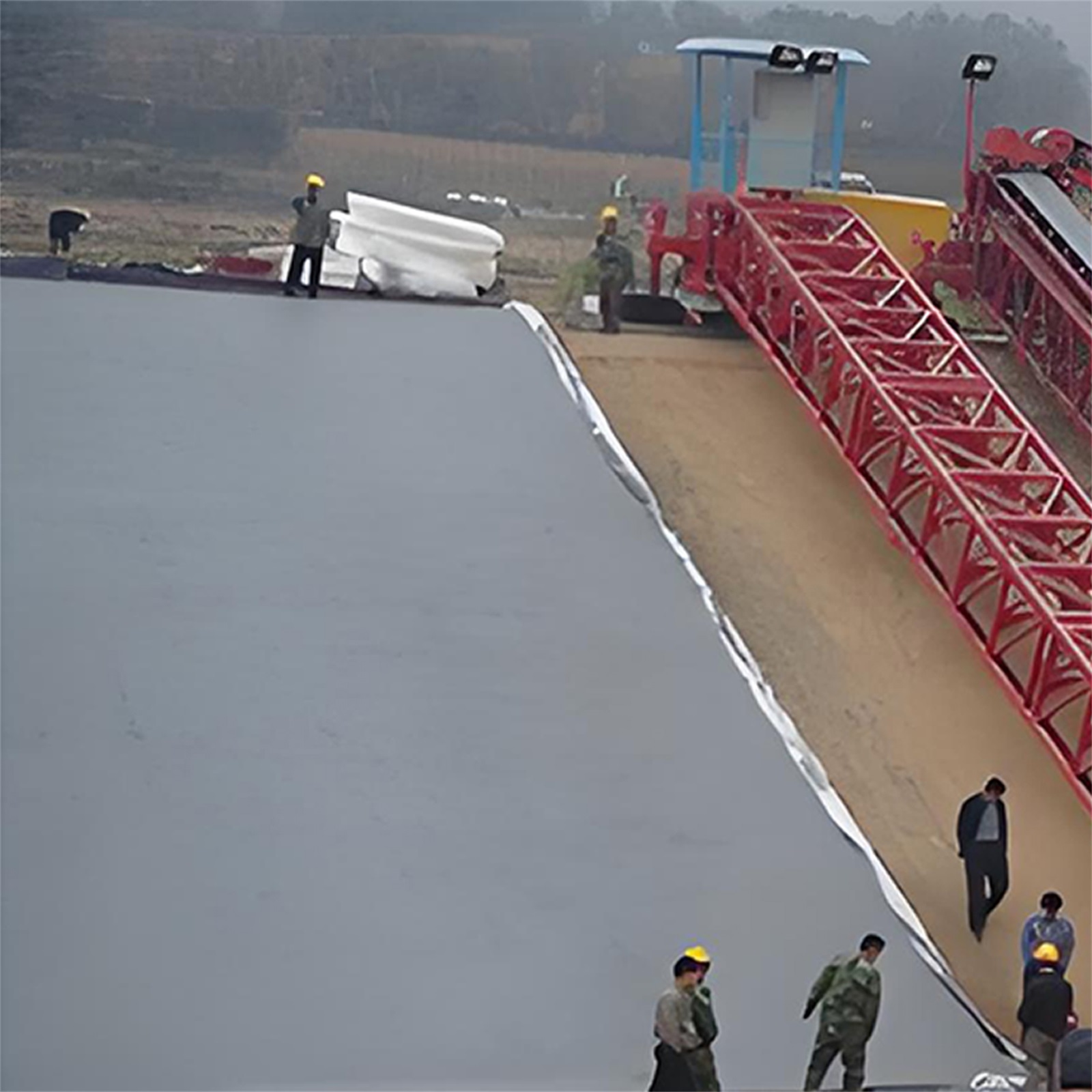

Products Application:Underground engineering and transportation infrastructure, water conservancy and water supply engineering, nuclear power and energy facilities, industrial and civil buildings, environmental protection and municipal facilities, agriculture and special engineering etc.

|

Model |

RH120-RH120-RH90 |

RH130/26+RH130/26 |

RH95-RH85 |

|

Product stuchre |

+enhancement layer(Net) |

+enhancement layer(Net) |

+enhancement layer(Net) |

|

Preduct width |

2000mm |

2000-3000mm |

2000-3000mm |

|

Product thickness |

0.5-3mm |

0.8-3mm |

0.8-3mm |

|

Designed Capasty |

1500kg/h |

1500mg/h |

4000kg/h |

|

Host Model |

Single Screw RH-150 |

Single Screw RH-180 |

Single Screw RH-200 |

Parallel Twin Screw RH-95 |

Parallel Twin Screw RH-135 |

|

Raw Material |

LDPE、LLDPE、 HDPE、EVA、ECB、M-PE |

LDPE、LLDPE、 HDPE、EVA、ECB、M-PE |

LDPE、LLDPE、 HDPE、EVA、ECB、M-PE |

LDPE、LLDPE、 HDPE、EVA、ECB、M-PE |

LDPE、LLDPE、 HDPE、EVA、ECB、M-PE |

|

Width(mm) |

3000-4000 |

4000-6000 |

6000-8000 |

4000-8000 |

4000-8000 |

|

Thickness(mm) |

1.0-3.0 |

1.0-3.0 |

1.0-3.0 |

1.0-3.0 |

1.0-3.0 |

|

Output(kg/h) |

650-850 |

850-1000 |

1000-1200 |

1200-1500 |

1200-1800 |

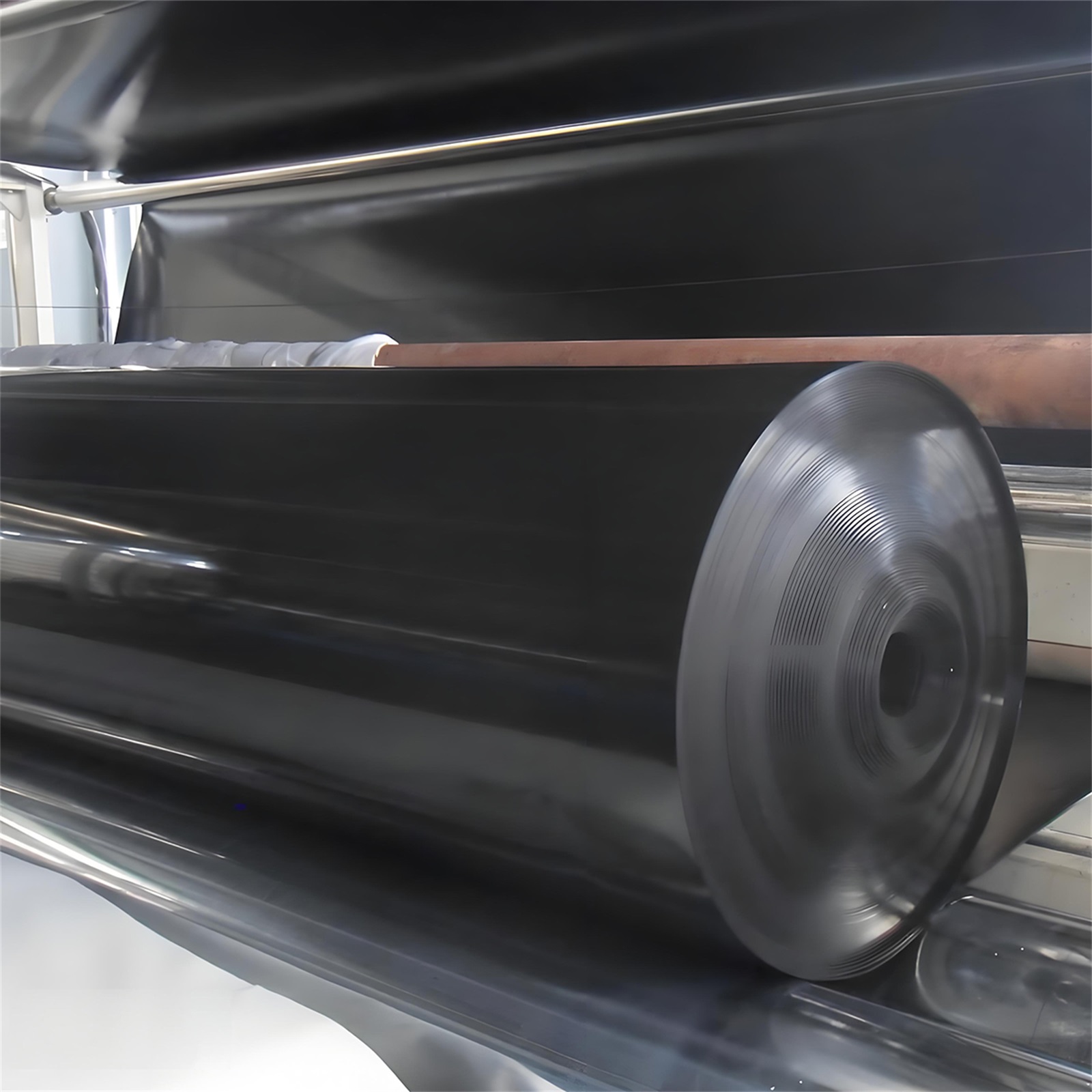

The surface of HDPE waterproofing membrane is flat, does not bulge, and has high density. HDPE waterproofing membrane achieves physical performance breakthroughs through high crystallinity molecular chain structure (crystallinity 90%+), and combines pre-laid anti-adhesion technology to innovate the reliability of waterproofing system. Its successful application in extreme environment projects such as nuclear power, subway, and landfill has verified its status as the core material of "lifetime waterproofing system". With the advancement of the dual carbon policy, HDPE will become the preferred solution for green building waterproofing.

Roof waterproofing of industrial and civil buildings, including planted roofs, flat roofs, sloping roofs, underground waterproofing of buildings: including waterproofing of reservoirs, dams, pools, tunnels, grain depots, civil air defense projects, landfills, artificial lakes, etc.

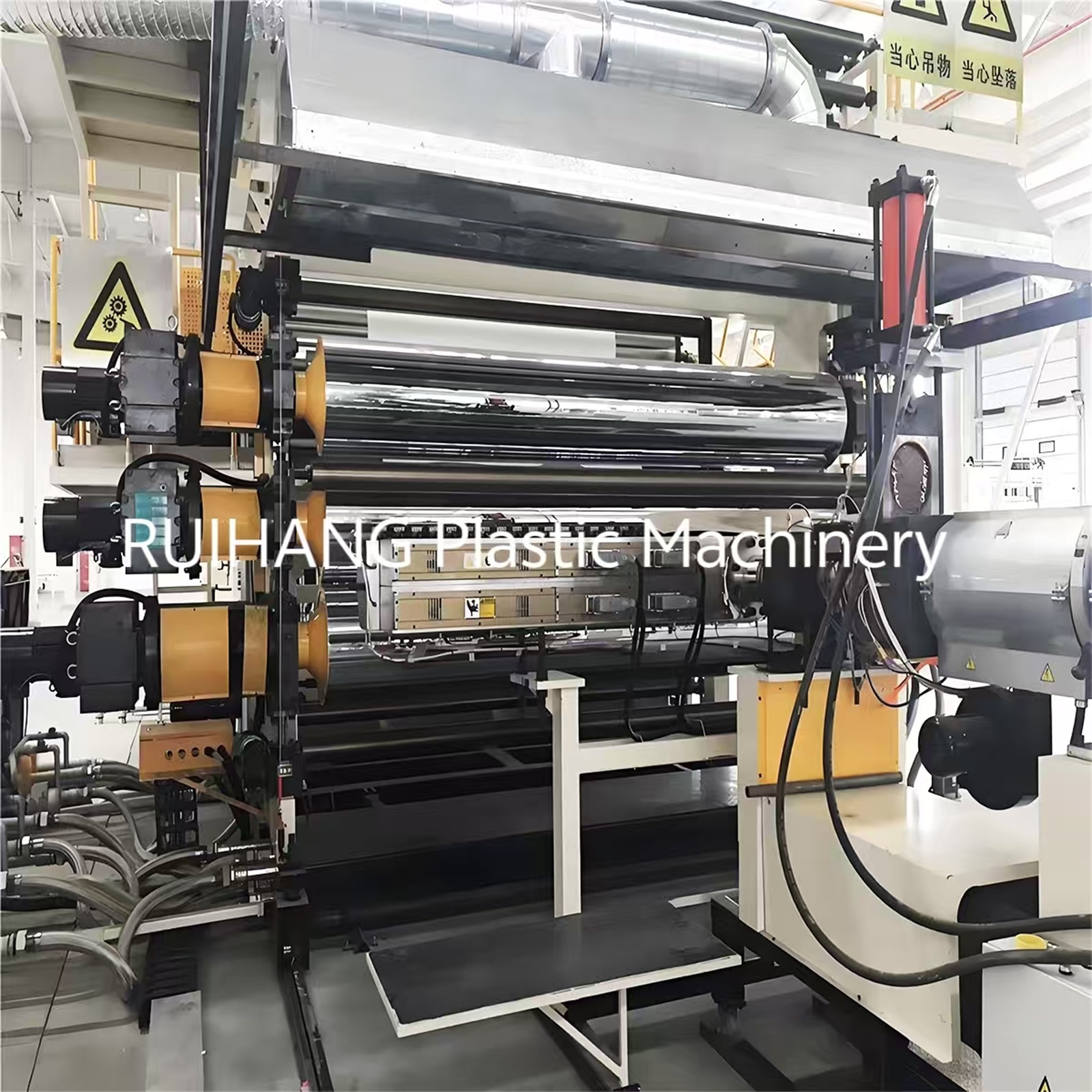

Twin-screw extruder, screen changer and hanger type mold, three-roll calender, cooling bracket, haul-off machine, cutter, winder and other auxiliary machinery.

4. 1. The cooling roller and stress-relieving cooling bed are used to make the film run smoothly and fully set, ensuring the shrinkage rate is less than 3%.

5. 2. The production line has the comprehensive characteristics of high degree of automation, low power consumption, convenient operation, large output and low cost.

Adopting double-stage single screw technology, it improves energy efficiency and reduces energy consumption, with an hourly output of 1500-2000 kg, supporting the production of large-diameter pipes (diameter 1600-2800mm).

Equipped with nitrided steel screw and barrel, the forced lubrication system ensures uniform plasticization of the melt, supports multi-layer composite co-extrusion process, and can produce high-barrier and high-transparency materials.

The fully automated control system achieves high-precision production (error ±0.1%), equipped with 5G Internet of Things to achieve digital management and control, and supports remote monitoring and data collection.

Through the optimization of components such as servo motors and melt cooling exchangers, the energy saving rate can reach 30%, and the fully automatic chipless cutting technology is used to reduce material waste.

Free on-site installation guidance and operational training

24/7 technical support with remote assistance

Lifetime maintenance consultation

◆ Proven Technology – Over 15 years of extrusion machine manufacturing experience

◆ Cost Saving – Energy-efficient design lowers your production costs

◆ Global Service – Technicians can be sent to to your facility for on-site installation and worker training