Model:RH-65/40/RH--75/40

Production Capacity:200 kg/h~350kg/h(Product width: 6mm-100mm)

Products Application:Reinforced structural engineering, environmental engineering, water conservancy engineering, transportation infrastructure, etc.

|

Main parameters |

|||

|

Extruder model |

Output strips |

Output( kg/h) |

Bandwidth range(mm) |

|

RH-65/40 |

2 |

200 |

6-32mm |

|

RH-75/40 |

2-6 |

300-350 |

50-100mm |

2.

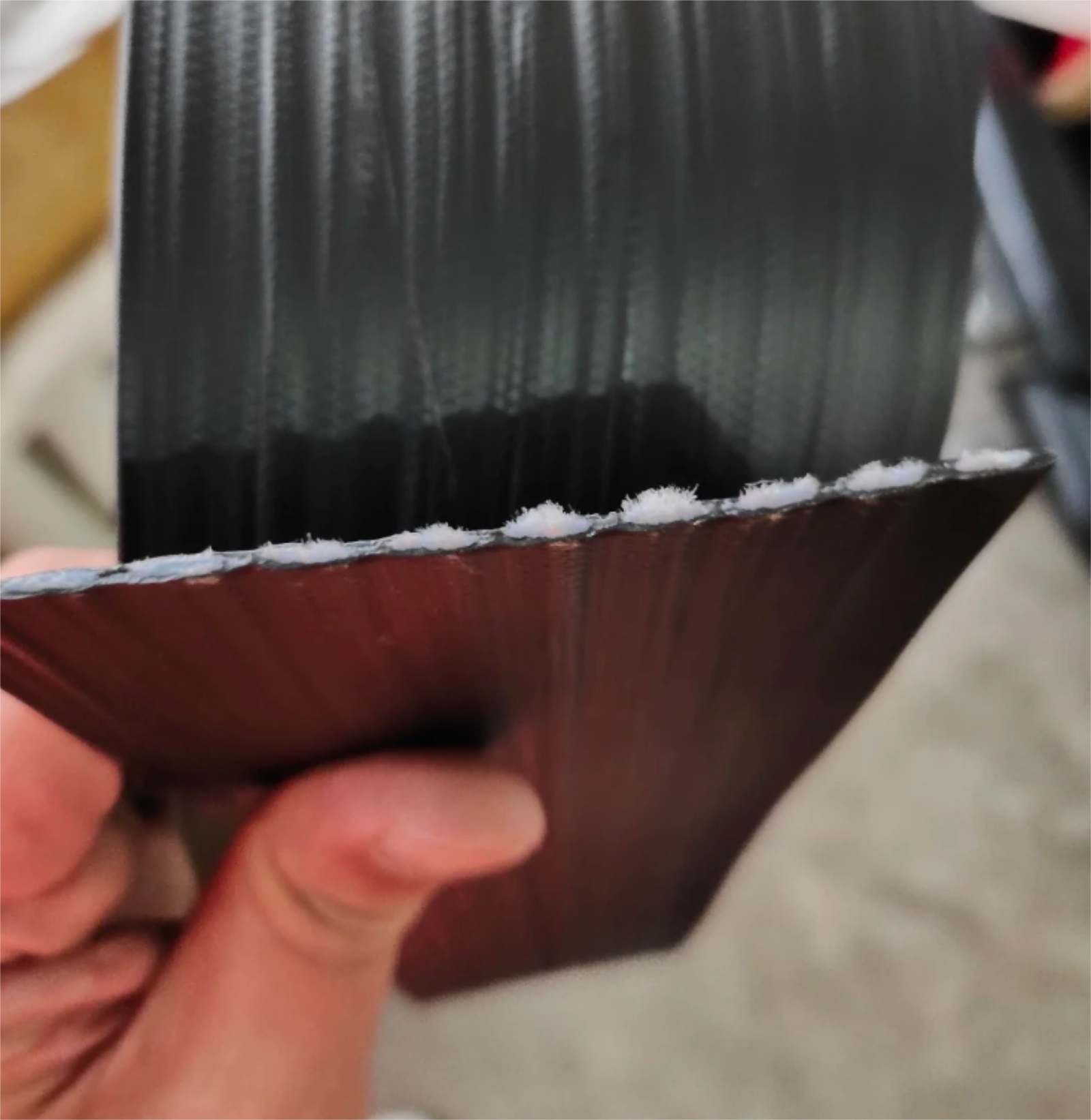

PE PET Fiber strapping band extrusion machine:PE PET fiber packing belt (polyester fiber flexible packing belt) is made up of many strands of polyester fiber, ls a safe, fast and economic packing strap. It has the characteristics of high strength, good weather resistance, safe use,high efficiency and environmental protection, etc.

In particular, it is light and easy to operate, uses a relatively simple buckle to tighten, does not require any energy (such as: power supply, compressed air) and does not require any auxiliary tools to tie a knot, and is applicable to a wide range of environments.

Application

It is used for packaging of goods during transportation, bundling of goods with delicate surfaces, bundling of goods with surface coatings, fastening of goods during transportation, bundling of materials, reinforcement of oil and gas pipelines, reinforcement of composite pressure vessels, reinforcement of buildings and civil engineering projects, etc.

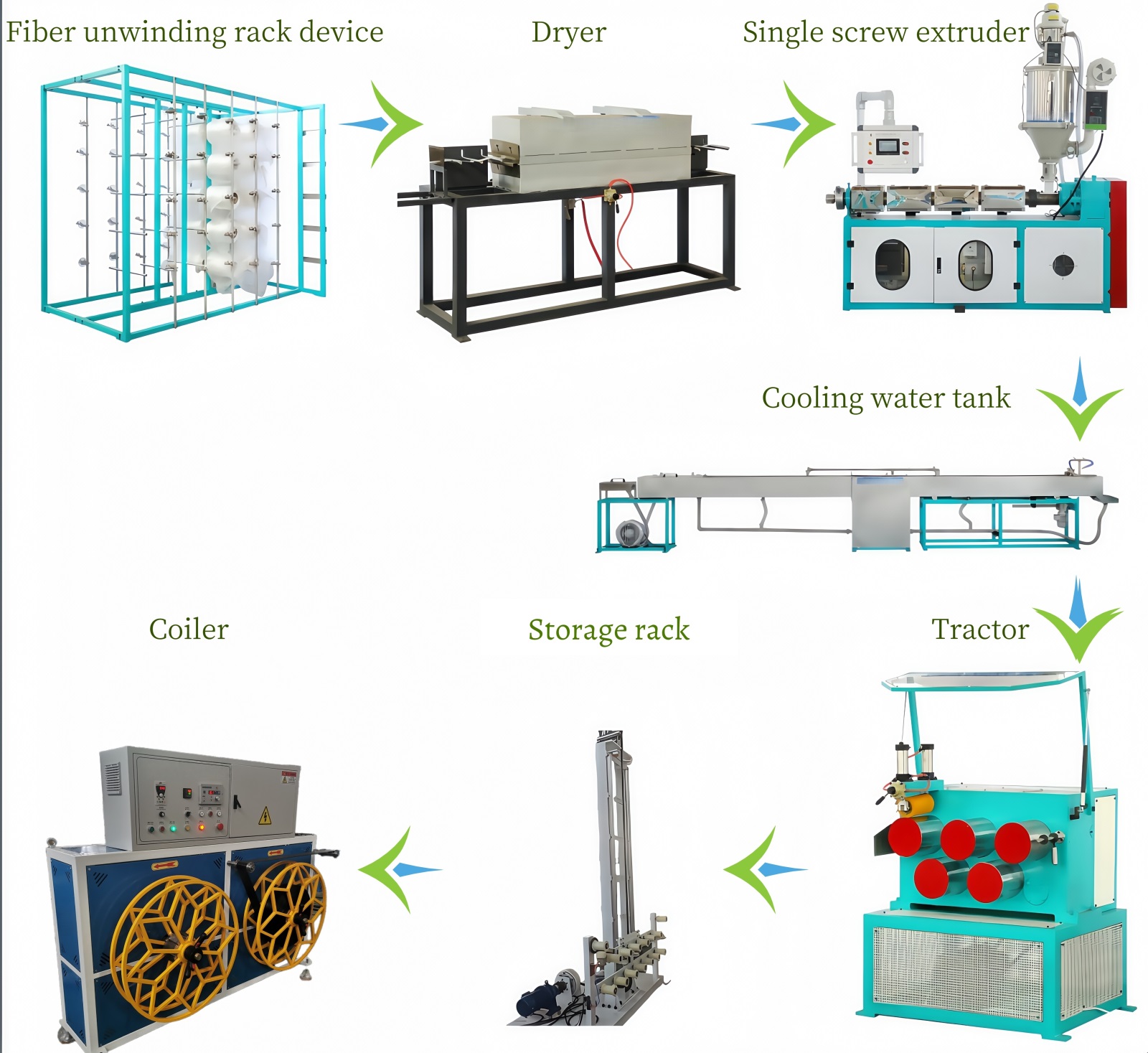

THE GEOSTRAP LINE INCLUDE FIBER CREELS, extruder, mould, cooling tank, haul off , Stocker , double station coiler.

Free on-site installation guidance and operational training

24/7 technical support with remote assistance

Lifetime maintenance consultation

◆ Proven Technology – Over 15 years of extrusion machine manufacturing experience

◆ Cost Saving – Energy-efficient design lowers your production costs

◆ Global Service – Technicians can be sent to to your facility for on-site installation and worker training