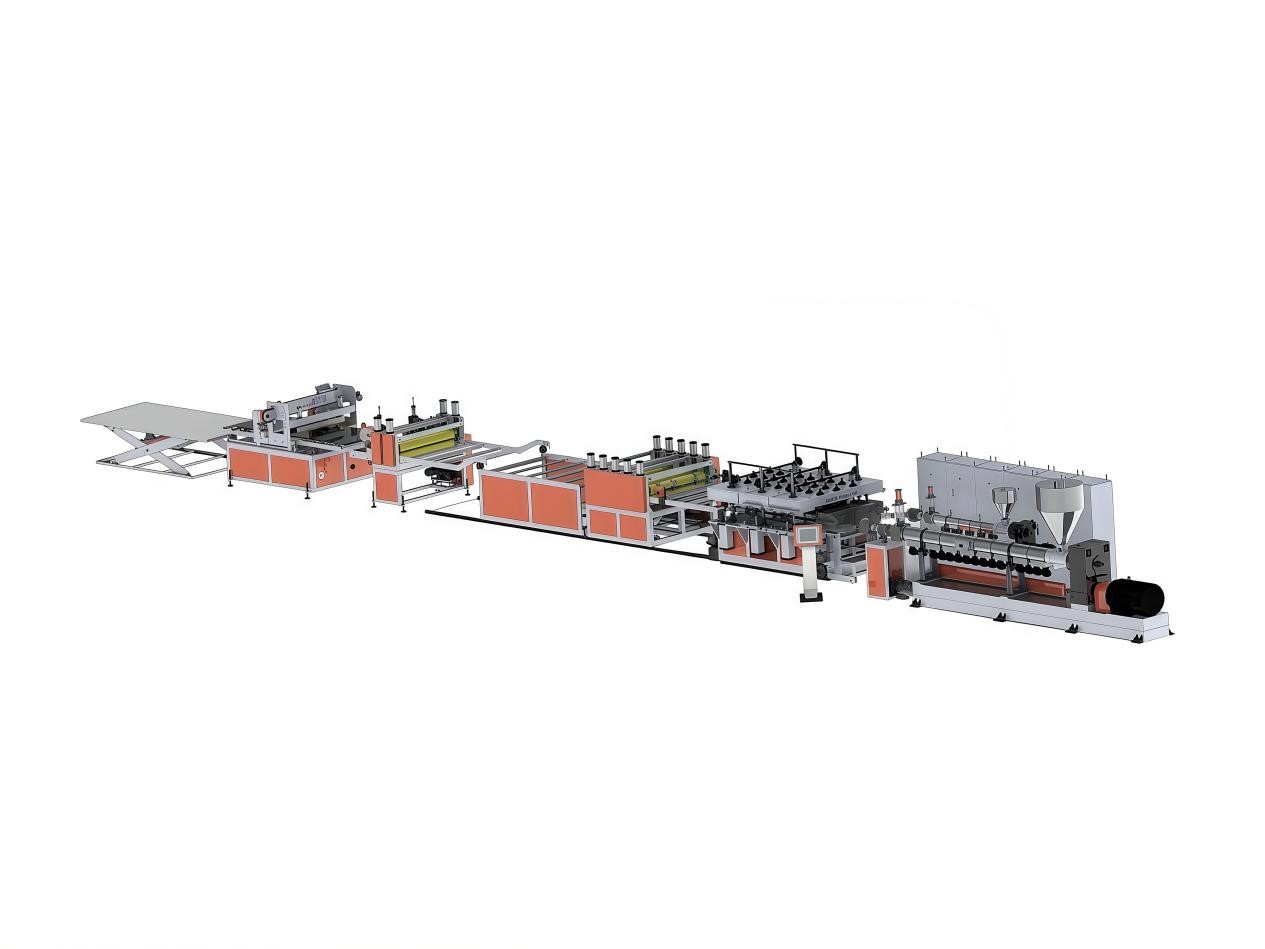

Model: RH-120/RH-150/RH-100+RH-65/RH-150+RH-90 (Width: 915mm–2000mm)

Production Capacity: 350kg/h–600kg/h

Products Application: The reusable container, packing case, clapboard, backing plate, and cutlet.

|

Specifications |

|||

|

Model |

Products width(mm) |

Products thickness(mm) |

Designed capacity(kg/h) |

|

RH-120 |

1200-2100 |

2-8 |

350 |

|

RH-150 |

1200-2600 |

2-8 |

500 |

|

RH-100+RH-65 |

2000 |

12-16 |

400 |

|

RH-150+RH-90 |

2000 |

12-16 |

600 |

PP hollow building formwork is a formwork material used in building construction. It is made of polypropylene (PP) material and has the characteristics of light weight, high strength and good weather resistance.

PP hollow building formwork is widely used in the field of construction, especially in large projects such as high-rise buildings, bridges, tunnels, etc. It can be used as a formwork for concrete pouring, providing support and protection, and it can also be used as a formwork for reinforced concrete structures, providing formwork support and a working platform for concrete pouring.

A. The extruder with exhaust structure does not require high moisture content of raw materials during the production process. The material will be discharged during the plasticization process to ensure the surface quality of the product;

B. Relying on technological innovation, after thoroughly improving the mold and the shaping plate, the production level of 915MM double-out products can be achieved. The product edge straightness is good, the production line process is stable, and the production capacity has also been greatly improved.

C. In terms of product cutting, based on the traditional cutting machine, the company combines the process requirements that hollow products cannot be dusted during the cutting process, and improves the cutting and dust collection structure, which can basically prevent the leakage of powder chips.

Through the multi-layer co-extrusion process, multi-layer hollow panels with different characteristics can be produced at the same time

Processes recycled PET flakes as efficiently as new material.

Remote Monitoring & Maintenance

Real-time fault diagnosis and online technical support minimize downtime.

User-Friendly Interface

Simple digital controls allow quick setup and easy operation.