Model:

φ50/70

φ65/85

φ80/100

φ100/125

φ125/150

φ150/175

φ175/200

φ200/225

Diameter of steel wire inside the pipe (mm): 1.5-2.5

Production Capacity(kg/h): 80~350

Products Application:

Urban power and communication engineering, residential areas and public facilities, industry and infrastructure, etc.

|

PECarbon Pipe Specifications |

Coil Quantity(m) |

Diameter of steel wire inside the pipe (mm) |

Weight comparison( kg/m) |

Ring stiffness (KN/㎡) |

Elongation at break (%) |

||||

|

Steel pipe |

PVC pipe |

PE carbon pipe |

PVC pipe |

PE carbon pipe |

PVC pipe |

PE carbon pipe |

|||

|

φ50/70 |

200 |

1.5 |

4.01 |

0.5 |

0.4 |

2.2 |

5.8 |

185 |

355 |

|

φ65/85 |

200 |

1.5 |

6.31 |

0.65 |

0.6 |

2.6 |

7.0 |

190 |

386 |

|

φ80/100 |

200 |

2.0 |

8.71 |

1 |

0.8 |

3.7 |

8.2 |

212 |

482 |

|

φ100/125 |

100 |

2.5 |

10.82 |

19 |

1.1 |

4.9 |

10.8 |

243 |

550 |

|

φ125/150 |

100 |

2.5 |

13.5 |

2.2 |

1.4 |

5.8 |

11.6 |

306 |

589 |

|

φ150/175 |

50 |

2.5 |

18.13 |

3 |

1.9 |

7 |

13.8 |

342 |

612 |

|

φ175/200 |

50 |

2.5 |

21.59 |

4.2 |

2.2 |

8.2 |

14.5 |

348 |

636 |

|

φ200/225 |

40 |

2.5 |

29.15 |

6.5 |

2.5 |

9 |

17.3 |

360 |

685 |

Features and applications of the products produced:

It has a smooth inner wall spiral structure; compared with flat wall tubes, it effectively reduces the friction on the wires and optical cables, and the direct friction coefficient is reduced by 60% compared with flat wall tubes. Because of its unique inner wall spiral, it provides good ventilation and heat dissipation space for wires and optical cables, thereby effectively extending the service life of wires and optical cables and reducing maintenance costs.

It has the advantages of high toughness, high corrosion resistance, high insulation resistance, good flame retardancy, light weight, long life, and not easy to deform with crustal changes.

It is widely used in underground projects of urban street lamp lines, underground projects of laying electric railway power and communication cables, construction and renovation projects of highway power and communication facilities, residential community construction projects, parks and large underground cable projects. It is currently an ideal underground cable sheath pipe.

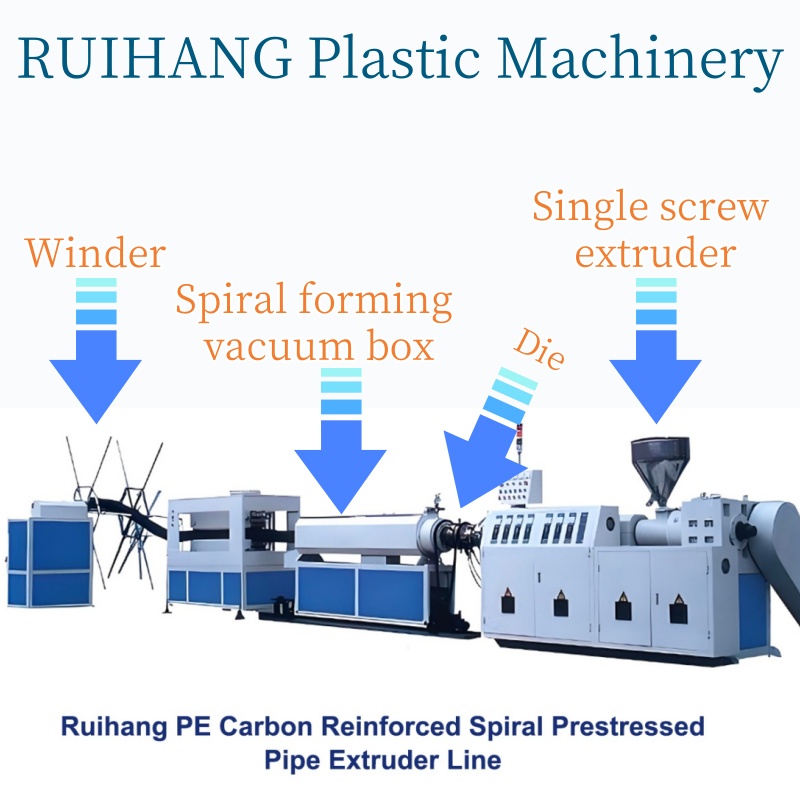

1. Equipped with a special single-screw extruder for PE, the special design structure has the advantages of fast extrusion and fast plasticization

2. Professional spiral extrusion mold, reasonable flow channel design, and the extruder make the inner and outer walls of the pipe smooth

3. After repeated tests, the spiral copper sleeve has a reasonable match for the slot width and length, which makes the pipe forming speed fast, saves raw materials, and has a significant cooling effect. The speed can reach 2.5Mmin

4. The spiral forming vacuum box is made of 304 stainless steel, with an efficient water pump and a special spray design, which brings fast forming speed.

Free on-site installation guidance and operational training

24/7 technical support with remote assistance

Lifetime maintenance consultation

◆ Proven Technology – Over 15 years of extrusion machine manufacturing experience

◆ Cost Saving – Energy-efficient design lowers your production costs

◆ Global Service – Technicians can be sent to to your facility for on-site installation and worker training

Ruihang Plastic Machinery is a direct manufacturer of extrusion machines, based in Qingdao, China. With over 15 years of export experience, we've supplied high-quality machinery to 20+ countries worldwide.

Absolutely! Our experienced engineers can be dispatched to your facility for on-site installation and worker training. Alternatively, we offer remote online guidance for your team.

All our machines come with a 12-month warranty, and our technical team guarantees a response within 6 hours for any issues.

We provide free replacement parts (excluding wear-and-tear components) during the warranty period. For consumable parts, we charge only a minimal cost fee.

Production time varies based on specifications, but standard orders typically take 3-4 months. We'll provide a precise timeline after reviewing your requirements.

We offer live video testing before shipment, along with detailed inspection reports and videos. You're also welcome to visit our factory for on-site testing.

Definitely! We specialize in tailored solutions-just share your needs, and we'll design machinery to match your exact specifications.