Model: RH-55/RH-65/RH-75 (Pipe diameter range: 20mm–160mm)

Production Capacity: 160kg/h–350kg/h

Products Application:

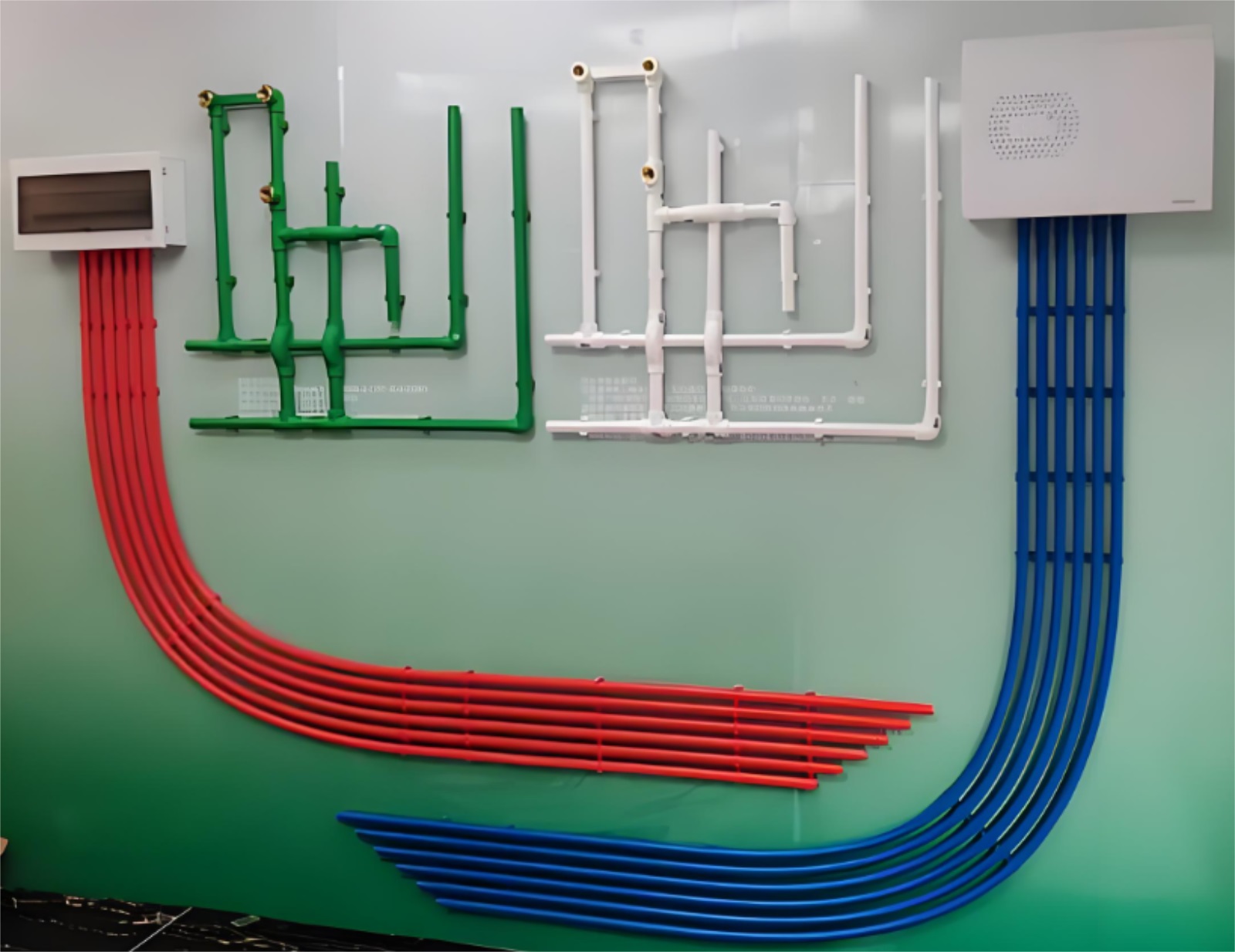

Solar energy, thermal energy circulation system, HVAC and tap water supply and other fields

PP-R glass fiber composite pipe is an upgraded product of PP pipe. It is manufactured by three-layer co-extrusion process. The middle layer is glass fiber reinforced material, and the inner and outer layers are made of hot water material and imported PP-R raw materials respectively.

It is mainly used in the fields of solar energy, thermal energy circulation system, HVAC and tap water supply.

|

Model/Parameter |

Pipe diameter range |

Extruder Model |

Co-extrusion machine model |

Production speed |

Maximum output |

Installed capacity |

Size |

Weight |

|

RH-55/55 |

20-63mm |

LSJ55/33 |

SJ-25/25 |

1-10m/min |

160 Kg/h |

140kw |

32*3.0*2.2m |

9.5t |

|

RH-65/65 |

75-110mm |

LSJ65/33 |

SJ-30/25 |

0.2-4.5m/min |

260 Kg/h |

180kw |

36*3.1*2.2m |

12.5t |

|

RH-75/75 |

75-160mm |

LSJ75/33 |

SJ-30/25 |

0.5-5m/min |

350kg/h |

220KW |

38*3.1*2.2m |

14t |

Specialized single screw extruder, with high-speed extrusion, efficient plasticization and other characteristics. Professional separation type mixing screw, specially designed three extrusion heads, reasonable path, smooth outer and inner walls of the pipe, small internal stress.

Adopt Siemens PLC control system, support multi-point closed-loop control, real-time monitoring of heating temperature, melt pressure, traction speed and other parameters to ensure production synchronization.

Equipped with servo motor-driven traction machine and cutting machine, high-speed and stable operation can be achieved.

Use adjustable co-extrusion composite molds, and the wall thickness of each layer can be controlled by adjusting the mold thickness. There is no need to change the extruder speed, which reduces the requirements for operating skills.

The mold material is 40Cr high-quality mold steel, which is resistant to high temperature and corrosion, and is suitable for long-term high-temperature production environment.

Adopt stainless steel vacuum shaping box (such as S304 stainless steel), combined with spray and immersion cooling, to ensure that the pipe is quickly shaped and has a smooth surface.

The vacuum controllable device maintains production stability and avoids deformation problems caused by vacuum fluctuations.

Equipped with a combined cutting system, it uses chipless cutting technology for pipes of different diameters, and the cuts are smooth and burr-free.

The weightless metering feeding device optimizes the utilization of raw materials, reduces raw material waste and improves the consistency of finished products.

By replacing the mold, it can adapt to the production of 20-160mm diameter pipes and is compatible with three-layer and four-layer structure adjustments.

Some equipment supports fast switching of PP-R, PE-RT and other material production, reducing the idle rate of equipment.