Model:RH-45/RH-55/RH-65/RH-75(Diameter Range(mm):Φ6-Φ50)

Production Capacity: 20 kg/h~110 kg/h

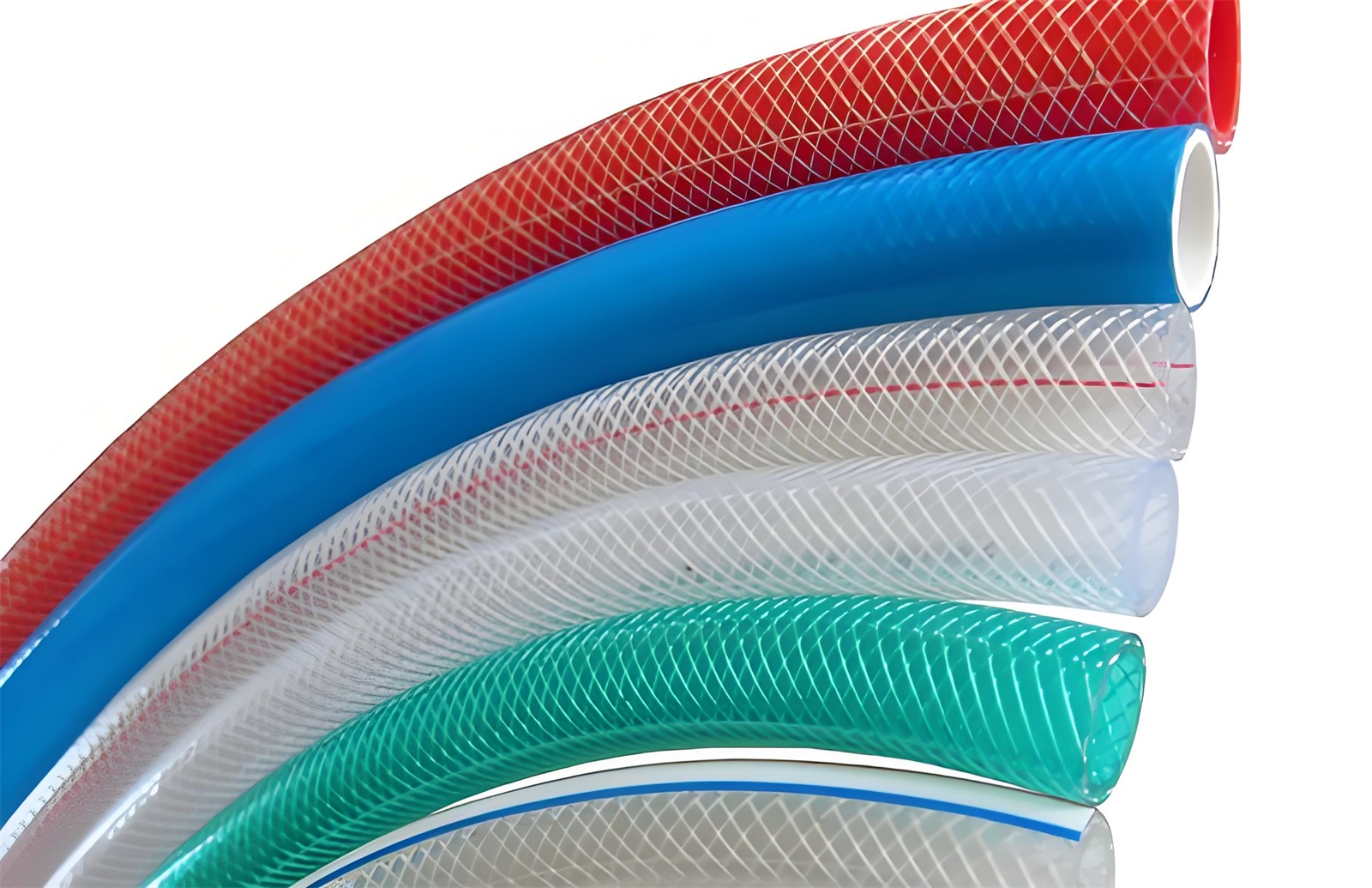

Products Application:It is suitable for transporting pressurized or corrosive gases and liquids, and is widely used in machinery, coal mining, petroleum, chemical industry, agricultural irrigation, construction, civil (solar water heaters, oil tanks) and other fields. It is also widely used in watering gardens and lawns.

|

Model |

RH-45 |

RH-55 |

RH-65 |

RH-75 |

|

Extruder |

SJ45/30 |

SJ55/30 |

SJ65/30 |

SJ75/30 |

|

Diameter Range(mm) |

Φ6-Φ16 |

φ8-φ25 |

φ12-φ50 |

φ20-φ50 |

|

Output(kg/h) |

20-40 |

30-60 |

40-80 |

60-110 |

|

Installed Power(kw) |

35 |

42 |

50 |

65 |

Embedded with polyester fiber or aramid fiber mesh reinforcement layer, it is tensile-resistant, high-pressure-resistant (working pressure can reach more than 1.0MPa), and not easy to burst.

It is lighter than rubber tubes, has a small bending radius, can be coiled for use, is easy to install, and is suitable for complex wiring scenarios.

It is resistant to acids, alkalis, greases and various chemical media, and is suitable for industrial fluid transportation (such as weak acids, alkaline solutions, etc.).

Some products add UV stabilizers and can be used outdoors, adapting to the temperature range of -10℃ to +60℃ (special formulas can be expanded).

The inner wall is smooth and the fluid resistance is small; the fiber layer enhances wear resistance and is suitable for granular media (such as sand, gravel, mud).

Models that meet food-grade standards (such as FDA, RoHS) can be used in drinking water or food industries.

1.Agricultural irrigation: mobile sprinkler and drip irrigation systems, weather-resistant and resistant to mechanical damage.

2.Industrial fluid transportation: chemical liquids, exhaust gas emissions, cooling water circulation, etc.

3.Building drainage: temporary drainage, basement pumping, light and easy to carry.

4.Firefighting assistance: lightweight fire hose, quick deployment.

5.Home and garden: car wash hose, garden watering, flexible and durable.

6.Mining/shipping: transport of particle-containing media or seawater (salt spray resistant models are required).

Fully automatic extrusion and weaving

Adopt PLC control system to realize continuous production of PVC inner tube extrusion, fiber braiding reinforcement layer (polyester/aramid), and outer layer coating, reduce manual intervention, and the production line speed can reach 20-50 meters/minute.

Online detection and deviation correction

Equipped with laser diameter gauge, tension sensor, etc., real-time monitoring of pipe thickness and fiber layer uniformity, automatic adjustment of process parameters, and ensure product consistency.

Multi-layer co-extrusion technology

Through the collaborative operation of multiple extruders, the melting temperature (160-200℃) and thickness of the inner tube, bonding layer, and outer layer are accurately controlled to avoid delamination or bubbles.

Adjustable fiber weaving angle

The CNC braiding machine can adjust the fiber winding angle (usually 45°-55°), optimize the pressure resistance and bending performance of the pipe, and adapt to different pressure level requirements (such as 0.3-1.5MPa).

Precise cooling and shaping

The segmented water cooling/air cooling system can quickly shape and reduce thermal stress to prevent deformation or uneven shrinkage.

Polymer modification technology

The production line is compatible with modified PVC materials such as anti-UV agents, plasticizers (such as DINP), flame retardants, etc., to expand the applicable environment of the pipe (such as outdoor, mine).

Heat recovery and utilization

The extruder heating system is equipped with a waste heat recovery device to reduce energy consumption by 20%-30%, in line with green manufacturing standards.

Quick mold change design

Modular molds and braiding heads support fast switching of different calibers (Φ5mm-Φ150mm) and reinforcement layers (single layer/double layer) to adapt to multi-specification orders.

Customized production

By adjusting the formula (such as food-grade PVC) or process, special hoses such as antibacterial and antistatic can be produced.

MES system integration

Production data (temperature, speed, pressure, etc.) are uploaded to the manufacturing execution system in real time to achieve quality traceability and process optimization.

AI defect detection

Automatic quality inspection based on machine vision can identify defects such as surface scratches and fiber dislocation, and the rejection rate of defective products is >99%.

Low VOC emissions

The closed mixing and extrusion system, combined with the exhaust gas treatment device, reduces the release of harmful gases during the plasticization process.

Waste recycling

The scraps can be directly mixed and used after being crushed, and the material utilization rate is more than 95%.