Model:RH-160/RH-250/RH-630 (Pipe Diameter Range: 50mm–630mm)

Production Capacity: 480kg/h–750kg/h

Products Application:Agricultural water supply and drainage, building water supply and drainage, power, communication cable laying, etc.

|

Technical Specifications |

|||

|

Model |

RH-160 |

RH-250 |

RH-630 |

|

Extruder |

Φ65/132 |

Φ80/156 |

Φ92/188 |

|

Drive Power(KW) |

37 |

55 |

110 |

|

Pipe Diameter Range(mm) |

Φ50-Φ160 |

Φ110-Φ250 |

Φ315-Φ630 |

|

Installed Capacity(KW) |

100 |

160 |

220 |

|

Dimensions(m) |

28*2*2.6 |

32*3*3 |

42*4*4 |

Large-diameter PVC pipes (usually those with a nominal diameter of DN200 or above, such as DN200, DN250, DN315, DN400, DN500, DN630, etc.) have significant advantages over other pipes (such as concrete pipes, steel pipes, and cast iron pipes) in many engineering applications due to their unique material properties. The following are its main advantages:

Excellent corrosion resistance, ensuring ultra-long life.

Excellent hydraulic performance and energy-saving effects brought by smooth inner wall.

Convenient transportation and installation and cost savings due to light weight.

Reliable and convenient connection method and good sealing.

Significantly low life cycle cost.

These advantages make large-diameter PVC pipes widely used in the following fields:

Municipal engineering: urban water supply main pipe/distribution pipe, drainage and sewage main pipe/branch pipe, rainwater discharge pipe.

Industrial field: factory water supply and drainage, industrial wastewater/chemical medium transportation pipeline, cooling water pipeline.

Water conservancy project: agricultural irrigation main canal, water diversion project.

Power and telecommunications: cable protection sleeve.

Mines: slurry transportation, ventilation ducts.

Seawater utilization: seawater desalination water intake and drainage pipes, seawater cooling water pipes.

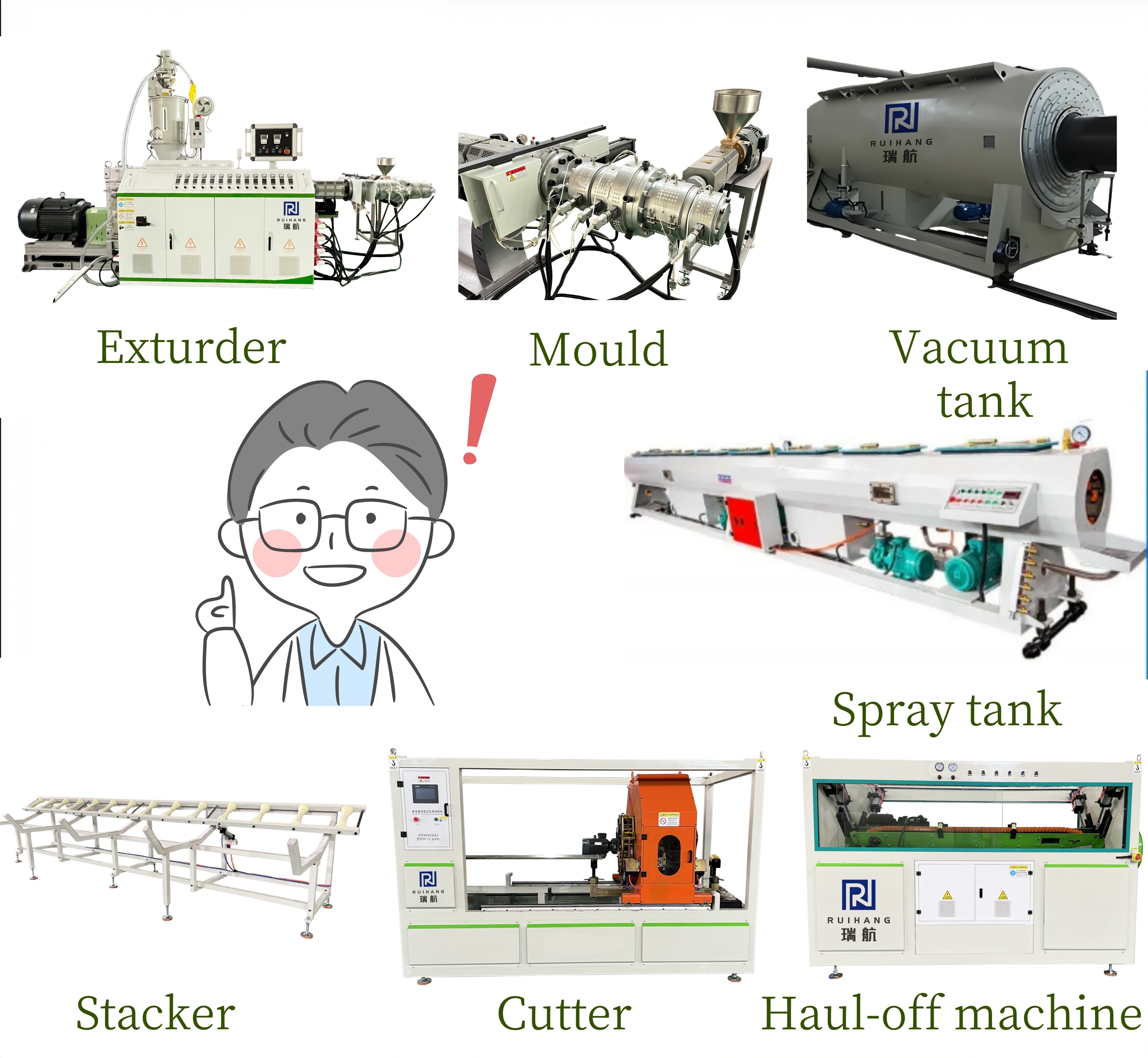

Conical twin-screw extruder, vacuum shaping table, haul-off machine, cutting machine, turning rack, etc.

Main features of the production line: