Model:RH-25/RH-50/RH-102/RH-150 (Diameter Range(mm):12-150)

Production Capacity: 6.4t~10.5t

Products Application:

It is widely used in industries such as industry, agriculture, food and medicine, construction, wind power, etc., to absorb and discharge liquids, solid particles, and powdered materials such as oil and low-concentration chemicals.

|

Model/Parameters |

Pipe range |

Extruder model |

Production speed |

Maximum Output |

Installed Capacity |

Production Line Dimensions |

Weight (t) |

|

RH-25 |

12-25mm |

LSJ45/25 |

1-10 m/min |

40 kg/h |

30kw |

12*3.6*2.5m |

6.4 |

|

RH-50 |

20-50mm |

LSJ65/25 |

1-8 m/min |

50 kg/h |

42kw |

15*3.6*2.5m |

7.1 |

|

RH-102 |

50-102mm |

LSJ90/25 |

0.5-6 m/min |

70 kg/h |

60kw |

18*3.6*2.5m |

9 |

|

RH-150 |

75-150mm |

LSJ120/25 |

0.5-4 m/min |

90 kg/h |

80kw |

20*3.6*2.5m |

10.5 |

Features and applications of the products produced:

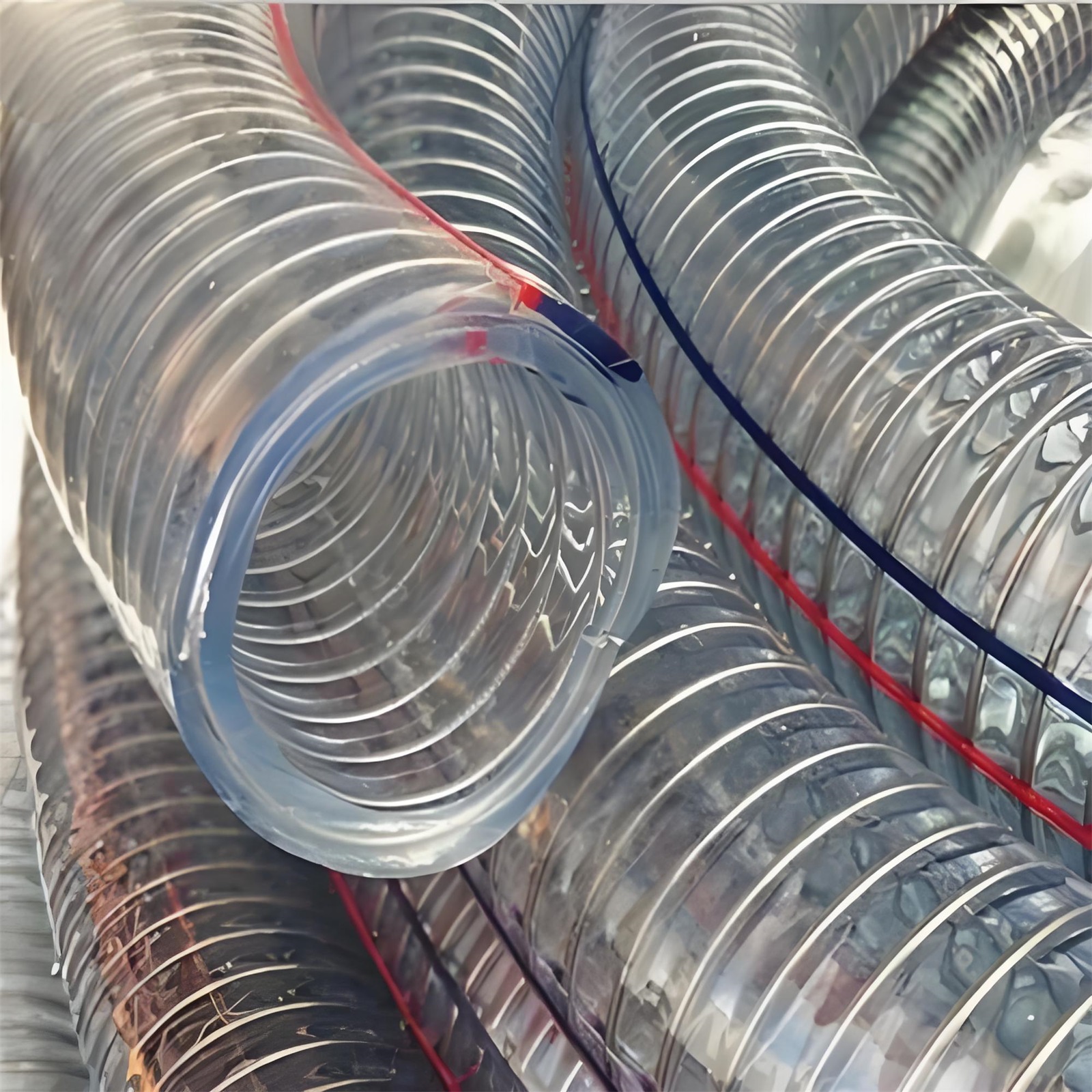

The inner and outer walls are uniform and smooth without bubbles. It has the advantages of pressure resistance, oil resistance, corrosion resistance, acid and alkali resistance, good flexibility, no brittle cracking, and not easy to age. It can replace ordinary rubber reinforced pipes, PE pipes, hard PVC pipes and some metal pipes.

It is widely used in industries such as industry, agriculture, food and medicine, construction, wind power, etc., to absorb and discharge liquids, solid particles, and powdered materials such as oil and low-concentration chemicals.

Extruder, wire spring winding machine, spray water tank, traction machine, coiling machine

High-speed and high-efficiency extruder is used to ensure the plasticization quality and output of materials.

Specially designed wire spring winding machine, uniform spring winding, long continuous production time.

Specially designed pipe head produces pipes with high transparency, uniform steel wire distribution, and arbitrarily set length.