Model: RH-25/RH-50/RH-102/RH-150

Diameter Range(mm): 12-150

Production Capacity: 6.4t~10.5t

Products Application:

It is widely used in industries such as industry, agriculture, food and medicine, construction, wind power, etc., to absorb and discharge liquids, solid particles, and powdered materials such as oil and low-concentration chemicals.

|

Model/Parameters |

Pipe range |

Extruder model |

Production speed |

Maximum Output |

Installed Capacity |

Production Line Dimensions |

Weight (t) |

|

RH-25 |

12-25mm |

LSJ45/25 |

1-10 m/min |

40 kg/h |

30kw |

12*3.6*2.5m |

6.4 |

|

RH-50 |

20-50mm |

LSJ65/25 |

1-8 m/min |

50 kg/h |

42kw |

15*3.6*2.5m |

7.1 |

|

RH-102 |

50-102mm |

LSJ90/25 |

0.5-6 m/min |

70 kg/h |

60kw |

18*3.6*2.5m |

9 |

|

RH-150 |

75-150mm |

LSJ120/25 |

0.5-4 m/min |

90 kg/h |

80kw |

20*3.6*2.5m |

10.5 |

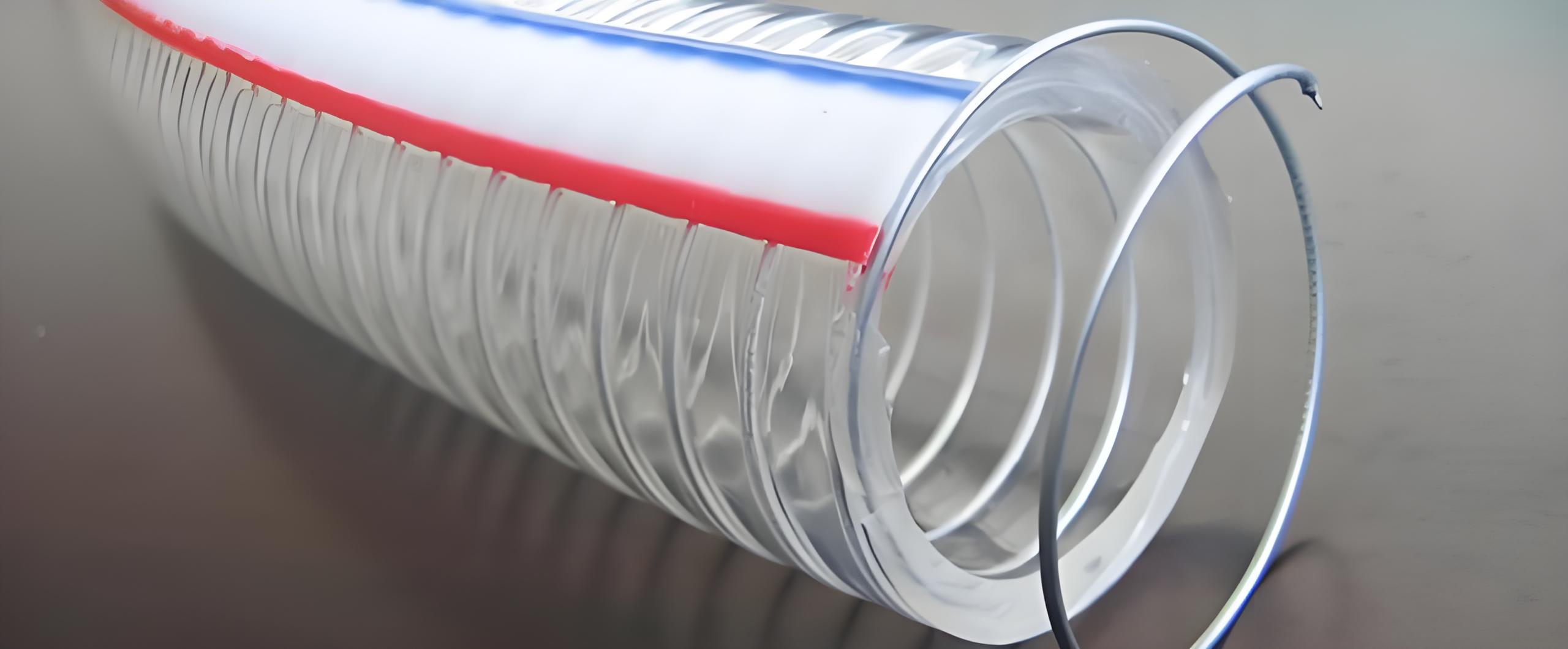

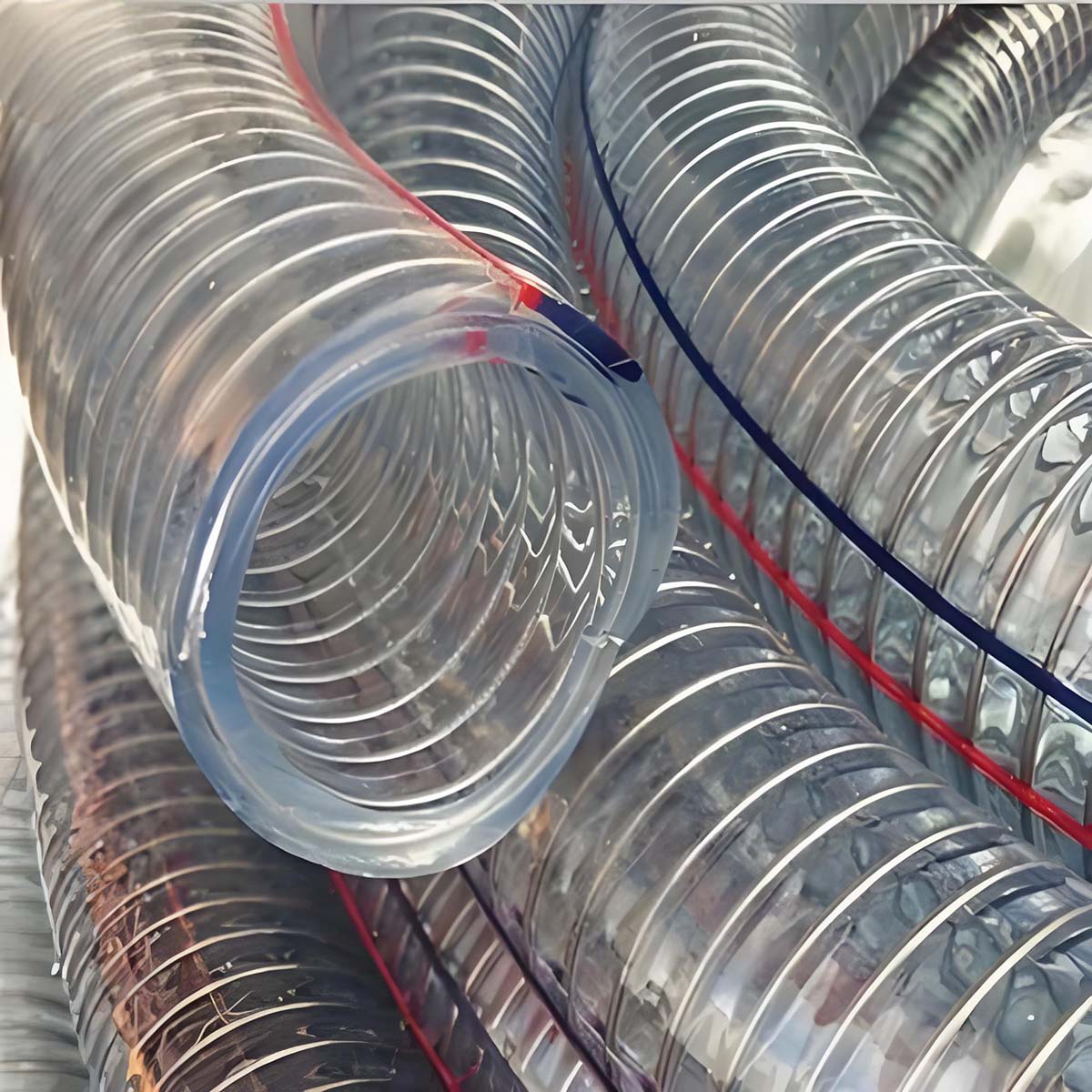

Features and applications of the products produced

:

The inner and outer walls are uniform and smooth without bubbles. It has the advantages of pressure resistance, oil resistance, corrosion resistance, acid and alkali resistance, good flexibility, no brittle cracking, and not easy to age. It can replace ordinary rubber reinforced pipes, PE pipes, hard PVC pipes and some metal pipes.

It is widely used in industries such as industry, agriculture, food and medicine, construction, wind power, etc., to absorb and discharge liquids, solid particles, and powdered materials such as oil and low-concentration chemicals.

Extruder, wire spring winding machine, spray water tank, traction machine, coiling machine

High-speed and high-efficiency extruder is used to ensure the plasticization quality and output of materials.

Specially designed wire spring winding machine, uniform spring winding, long continuous production time.

Specially designed pipe head produces pipes with high transparency, uniform steel wire distribution, and arbitrarily set length.

Free on-site installation guidance and operational training

24/7 technical support with remote assistance

Lifetime maintenance consultation

◆ Proven Technology – Over 15 years of extrusion machine manufacturing experience

◆ Cost Saving – Energy-efficient design lowers your production costs

◆ Global Service – Technicians can be sent to to your facility for on-site installation and worker training

【公司/厂房照片】

服务承诺

免费安装指导与操作培训

24小时远程技术支持

终身维护咨询

选择理由

◆ 成熟技术 – 15年挤出设备制造经验

◆ 省钱 – 节能设计降低生产成本

◆ 本地服务 – 支持技术人员到现场进行装机和技术培训

FAQ

Q1: Are you a manufacturer or trading company?

Ruihang Plastic Machinery is a direct manufacturer of extrusion machines, based in Qingdao, China. With over 15 years of export experience, we've supplied high-quality machinery to 20+ countries worldwide.

Q2: Do you provide installation and staff training?

Absolutely! Our experienced engineers can be dispatched to your facility for on-site installation and worker training. Alternatively, we offer remote online guidance for your team.

Q3: What is the warranty period?

All our machines come with a 12-month warranty, and our technical team guarantees a response within 6 hours for any issues.

Q4: What if a machine part breaks down?

We provide free replacement parts (excluding wear-and-tear components) during the warranty period. For consumable parts, we charge only a minimal cost fee.

Q5: What's the lead time for a extrusion line?

Production time varies based on specifications, but standard orders typically take 3-4 months. We'll provide a precise timeline after reviewing your requirements.

Q6: How can we check machines before delivery?

We offer live video testing before shipment, along with detailed inspection reports and videos. You're also welcome to visit our factory for on-site testing.

Q7: Can you customize machines not listed on your website?

Definitely! We specialize in tailored solutions-just share your needs, and we'll design machinery to match your exact specifications.