Model: RH-180/RH-2540/RH-300

Maximum profile width : 180mm–300mm

Production Capacity: 350 kg/h~600 kg/h

Products Application: Construction industry, Industrial manufacturing ,Home furnishings and Other fields .

|

Technical Specifications |

|||

|

Type |

RH-180 |

RH-240 |

RH-300 |

|

Maximum profile width (mm) |

180 |

240 |

300 |

|

Total auxiliary power (kw) |

18.7 |

27.5 |

33.1 |

|

Cooling water capacity(m3/h) |

5 |

7 |

7 |

|

Compressed air pressure(MPa) |

0.6 |

0.6 |

0.6 |

Strong corrosion resistance: It can withstand acid and alkali corrosion and is suitable for scenes with complex chemical environments.

Lightweight design: The weight is only 50%-70% of aluminum alloy, which is easy to transport and install.

Cost controllable: The price is 30%-50% lower than that of aluminum alloy, and no post-processing such as electroplating and painting is required.

Environmental protection characteristics: The recyclability rate exceeds 90%, which is in line with the green and low-carbon trend.

Construction: doors and windows, curtain walls, guardrails, etc. account for more than60%.

Industrial: Equipment housing, shelves, pallets and other corrosion-resistant scenes.

Home: Sun room, decorative lines and other customized needs.

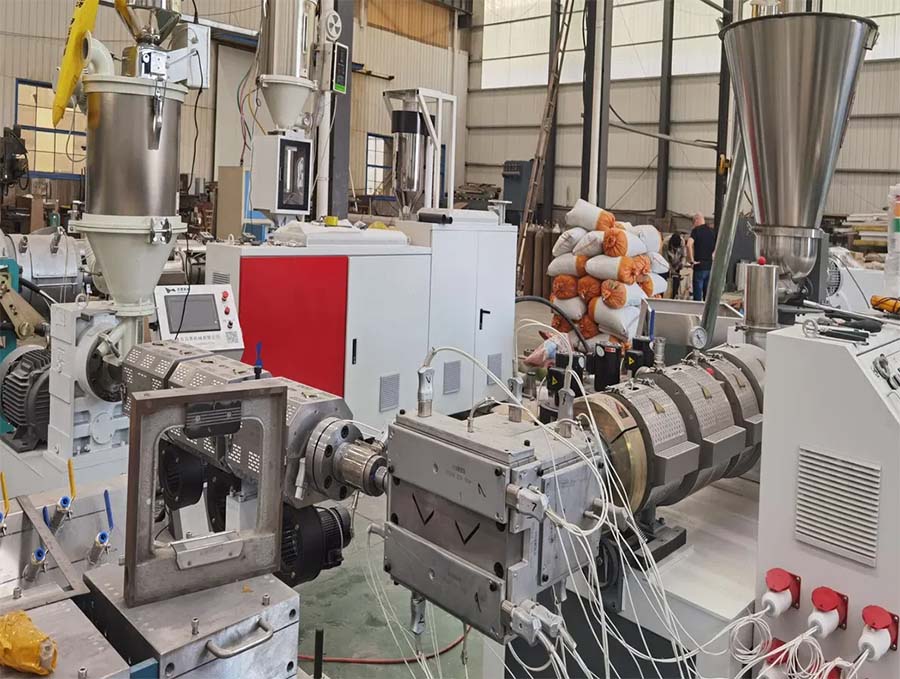

Extruder, head mold, setting platform, drawing machine, cutting machine, unloading table.

Conical twin screw extruder

Die head

Vacuum Forming machine

Hauling machine

Cutter + Stacker

4.Features of the production line:

1. Through continuous, automated, precise control (especially temperature control and vacuum shaping) and flexible production capacity (co-extrusion, rapid production change), high efficiency, high capacity, high quality, high consistency and low cost production are achieved.

2 It has good environmental protection and product adaptability, and can meet the market demand for diversified, high quality and high cost performance of PVC decorative panels.

1. Vacuum shaping + efficient cooling = ultra-high precision and stability: Solve the core pain points of decorative board size, appearance, deformation, etc.

2. Co-extrusion technology = functional integration and performance breakthrough: One-step method to achieve composite functions and create high value-added products.

3. Intelligent control = consistency, traceability and efficiency: Ensure stable quality, reduce defects, and optimize production.

4. Efficient screw/temperature control = high-quality plasticization and high-capacity foundation: Ensure material performance and production efficiency.

5. Modularity/quick change = production flexibility: Quickly respond to changing market needs.

6. Precision traction cutting = finished product accuracy: Ensure final product specifications.

Free on-site installation guidance and operational training

24/7 technical support with remote assistance

Lifetime maintenance consultation

◆ Proven Technology – Over 15 years of extrusion machine manufacturing experience

◆ Cost Saving – Energy-efficient design lowers your production costs

◆ Global Service – Technicians can be sent to to your facility for on-site installation and worker training

Ruihang Plastic Machinery is a direct manufacturer of extrusion machines, based in Qingdao, China. With over 15 years of export experience, we've supplied high-quality machinery to 20+ countries worldwide.

Absolutely! Our experienced engineers can be dispatched to your facility for on-site installation and worker training. Alternatively, we offer remote online guidance for your team.

All our machines come with a 12-month warranty, and our technical team guarantees a response within 6 hours for any issues.

We provide free replacement parts (excluding wear-and-tear components) during the warranty period. For consumable parts, we charge only a minimal cost fee.

Production time varies based on specifications, but standard orders typically take 3-4 months. We'll provide a precise timeline after reviewing your requirements.

We offer live video testing before shipment, along with detailed inspection reports and videos. You're also welcome to visit our factory for on-site testing.

Definitely! We specialize in tailored solutions-just share your needs, and we'll design machinery to match your exact specifications.