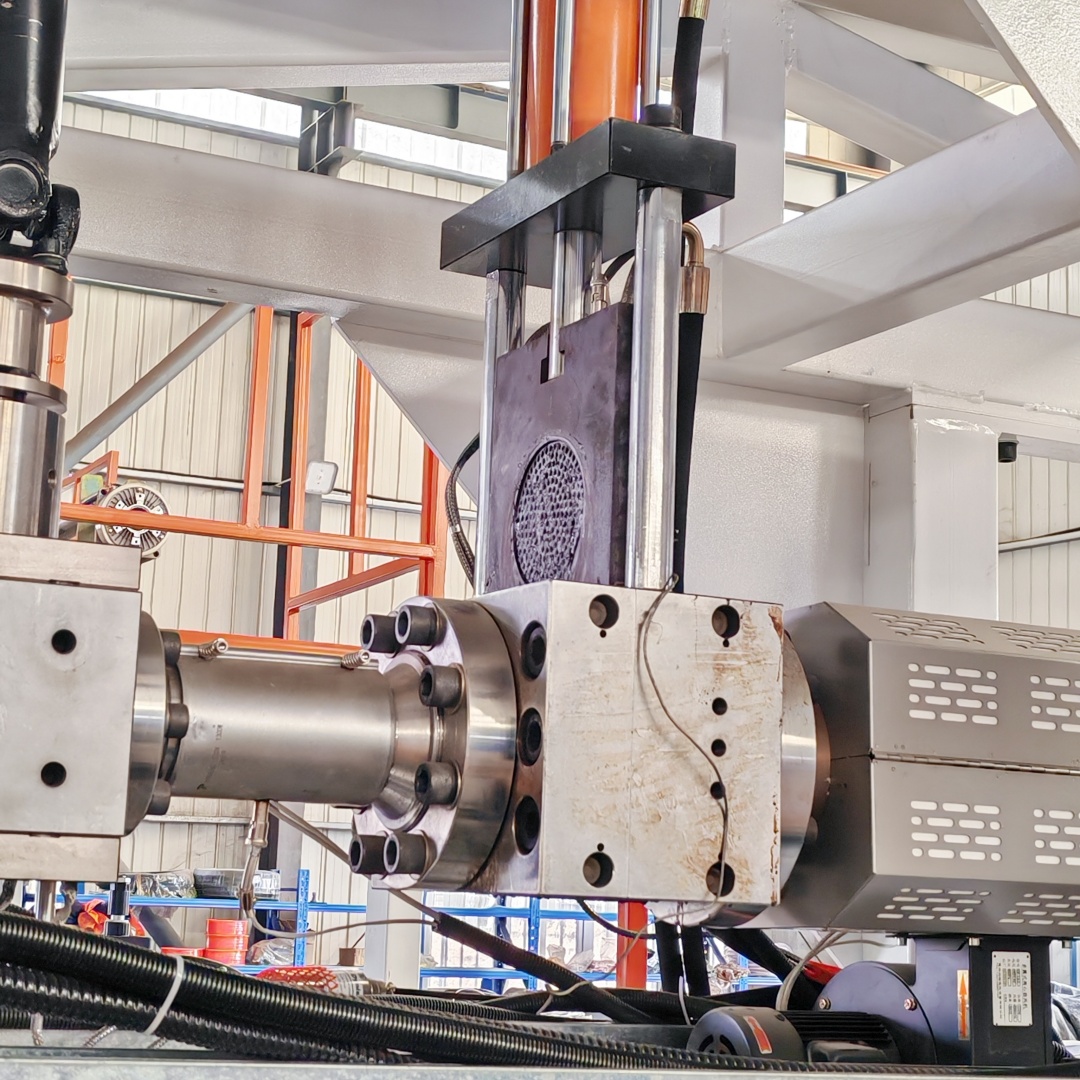

PE/PP sheets are flame retardant, high toughness, tensile and wear resistant, etc. PS (polystyrene) sheets are ultra-high transparency (light transmittance > 90%), high hardness, easy to print and low cost.

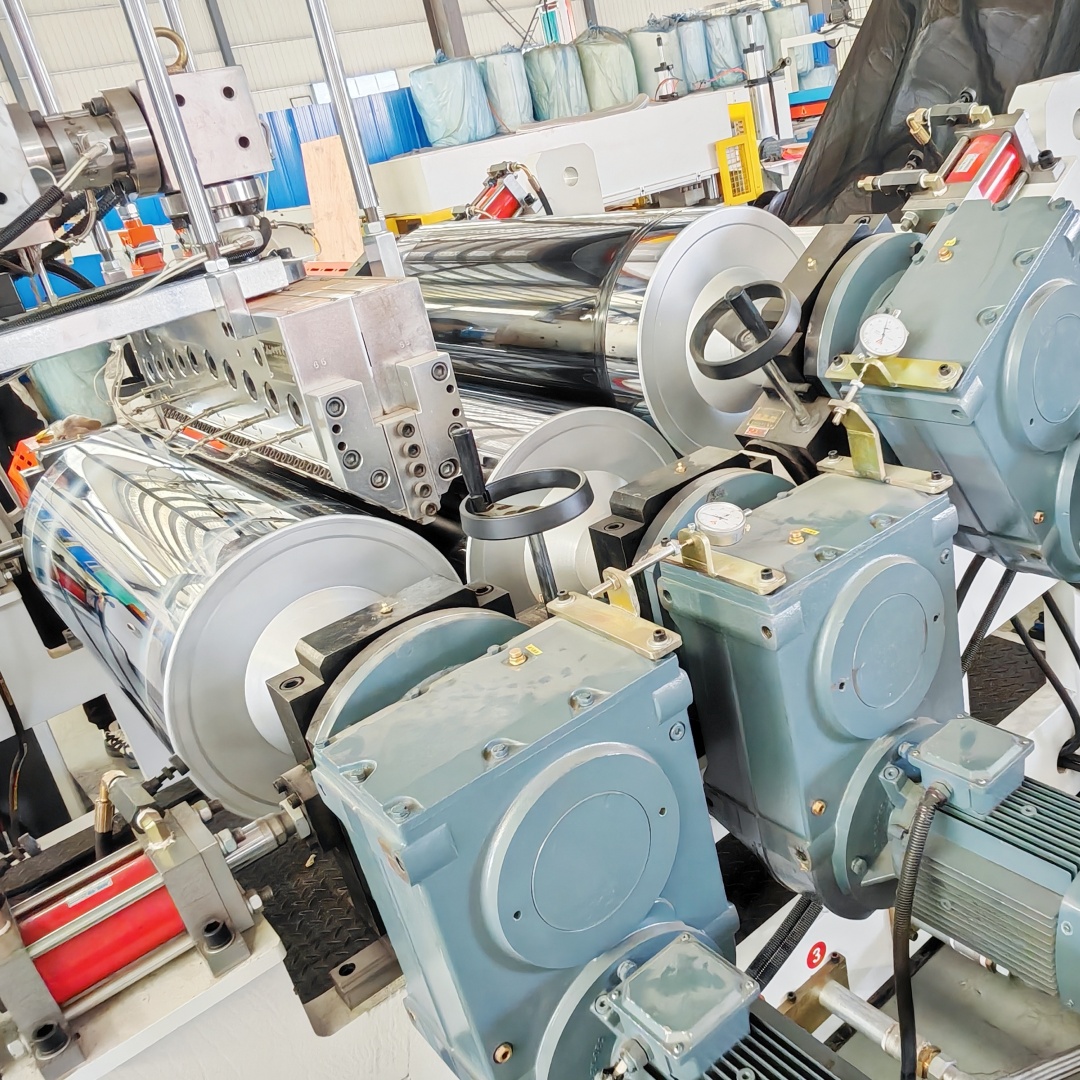

Model:RH105/65-1000/RH120/65-1000/RH130/90-1000/RH75/RH65-1000

Product Width(mm) : 600-1220

Production Capacity: 200 kg/h~1000kg/h

Products Application:Medical, food, chemical, clothing, packaging, electronics and other fields.

|

Model |

RH105/65-1000 |

RH120/65-1000 |

RH130/90-1000 |

RH75/RH65-1000 |

|

Suitable Material |

PP/PE/PS/ABS |

PP/PE/PS/ABS |

PP/PE/PS/ABS |

PP/PE/PS/ABS |

|

Sheet Thickness(mm) |

0.15-3.0mm |

0.15-3.0mm |

0.15-3.0mm |

0.15-3.0mm |

|

Width (mm) |

≤1220mm |

≤1220mm |

≤1220mm |

≤1220mm |

|

Max Output(kg/h) |

350-500 |

400-600 |

550-700 |

450-650 |