Model: RH105/65-1000/RH120/65-1000/RH130/90-1000/RH75/RH65-1000

Product Width(mm) : 600-1220

Production Capacity: 200 kg/h~1000kg/h

Products Application: Medical, food, chemical, clothing, packaging, electronics and other fields.

|

Model |

RH105/65-1000 |

RH120/65-1000 |

RH130/90-1000 |

RH75/RH65-1000 |

|

Suitable Material |

PP/PE/PS/ABS |

PP/PE/PS/ABS |

PP/PE/PS/ABS |

PP/PE/PS/ABS |

|

Sheet Thickness(mm) |

0.15-3.0mm |

0.15-3.0mm |

0.15-3.0mm |

0.15-3.0mm |

|

Width (mm) |

≤1220mm |

≤1220mm |

≤1220mm |

≤1220mm |

|

Max Output(kg/h) |

350-500 |

400-600 |

550-700 |

450-650 |

PE/PP sheets are flame retardant, high toughness, tensile and wear resistant, etc. PS (polystyrene) sheets are ultra-high transparency (light transmittance > 90%), high hardness, easy to print and low cost.

Application

Main uses of PP/PE/PS/ABS sheets:

*PP/PS blister sheets

*PP/PS single-layer sheets, PP/PS co-extruded two-color sheets, PP double-sided high-transparent sheets, etc. are used in the blister packaging industry.

*PP stationery sheets

*PP transparent sheets, frosted sheets (coarse sand, fine sand), two-color sheets, etc. are used in the stationery packaging industry.

*PP micro-foam sheets, PP foam sheets have advantages, PP foam sheets with a density greater than 0.45g/m3 have good bending resilience, are not easy to deform, and have broad prospects for use in the field of folders; PP foam sheets with a density of 0.6g/m3 have good mechanical properties and have a very broad future in the field of automotive interior decoration; they can be processed into carpet support materials, shading boards, sound insulation boards, luggage racks, interior decoration parts, covers, boxes, etc.; PP foam sheets with a density of 0.3g/m3 have good flexibility and resilience, and are suitable for packaging, partition boards and other fields.

PE sheets (polyethylene sheets) are mainly used in the packaging field, and common uses include:

PE sheets are important materials for plastic packaging and are used to produce plastic bags, films, containers and geomembranes. For example, daily necessities such as food packaging bags, buckets, and kettles are all made of PE sheets.

In the industrial field, PE sheets can be used to make pipes, wire and cable sheaths, etc. Its corrosion resistance makes it suitable for scenes where the stability of the material needs to be protected.

In the agricultural field, PE sheets are used to make agricultural films, which are used to cover farmland or greenhouses to keep warm and prevent rain.

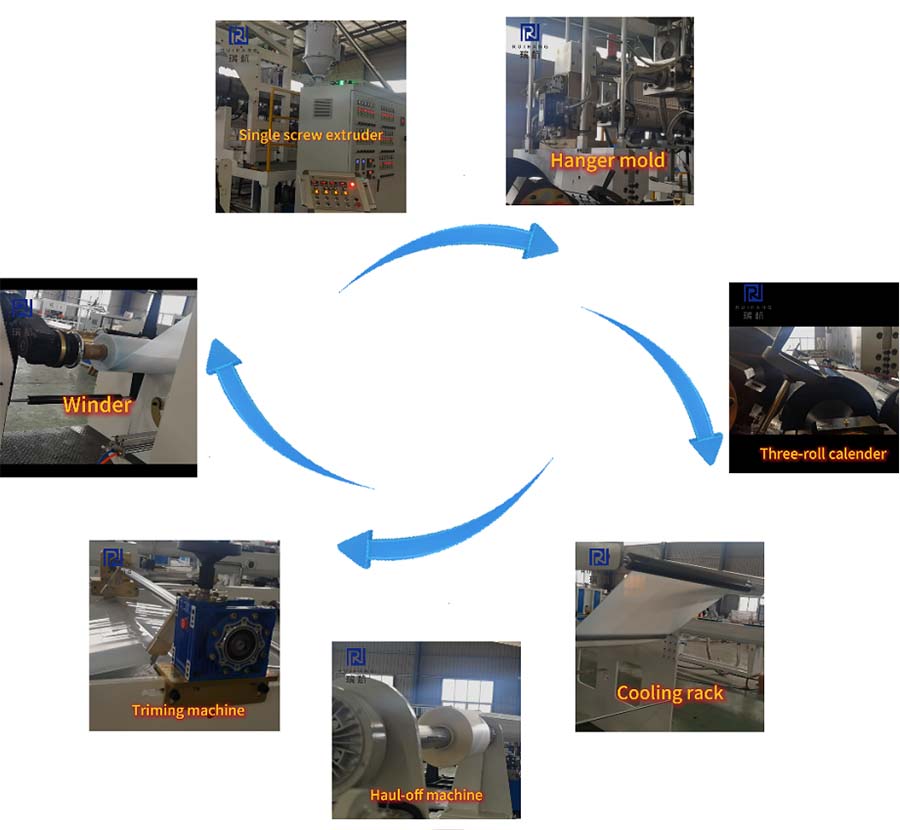

Single screw extruder, hanger type die, three-roll calender, cooling bracket, haul-off machine, shearing machine, transverse cutting machine, winder and other auxiliary machinery.

Main features of the production line:

1. Use multiple extruders to co-extrusion technology to produce multi-layer co-extruded composite PP and PS sheets, such as ABA, ABCBA, ABCDCBA and other multi-layer structures

2. Equipped with precision distributor, uniform layering, adjustable ratio of each layer, digital precision control.

3. Oblique horizontal tableting structure, more convenient operation and maintenance.

4. The roller is independently powered, and the line speed is synchronized with the extruder speed in closed-loop control.

5. The whole machine adopts PLC control to realize automatic control of parameter setting, data calculation and feedback, alarm and other functions.

Free on-site installation guidance and operational training

24/7 technical support with remote assistance

Lifetime maintenance consultation

◆ Proven Technology – Over 15 years of extrusion machine manufacturing experience

◆ Cost Saving – Energy-efficient design lowers your production costs

◆ Global Service – Technicians can be sent to to your facility for on-site installation and worker training

Ruihang Plastic Machinery is a direct manufacturer of extrusion machines, based in Qingdao, China. With over 15 years of export experience, we've supplied high-quality machinery to 20+ countries worldwide.

Absolutely! Our experienced engineers can be dispatched to your facility for on-site installation and worker training. Alternatively, we offer remote online guidance for your team.

All our machines come with a 12-month warranty, and our technical team guarantees a response within 6 hours for any issues.

We provide free replacement parts (excluding wear-and-tear components) during the warranty period. For consumable parts, we charge only a minimal cost fee.

Production time varies based on specifications, but standard orders typically take 3-4 months. We'll provide a precise timeline after reviewing your requirements.

We offer live video testing before shipment, along with detailed inspection reports and videos. You're also welcome to visit our factory for on-site testing.

Definitely! We specialize in tailored solutions-just share your needs, and we'll design machinery to match your exact specifications.