Model: SJZ80/156-1500/SJZ92/188-2200/RH 105/120/150

Product Width(mm) : 200–2400

Production Capacity: 350kg/h~550 kg/h

Products Application: Building materials, industrial products, packaging industry, consumer goods, special applications

|

Model |

Extruder Type |

Products Width |

Products Thickness |

Main Motor Power(kw) |

Max. Capacity(kg/h) |

|

SJZ80/156-1500 |

SJZ80/156 |

1220mm |

0.2-3.0mm |

75 |

350 |

|

SJZ92/188-2200 |

SJZ92/188 |

2000mm |

1.0-3.0mm |

110 |

550 |

|

Model |

Product Width |

Products Thickness |

Capacity Range |

|

RH 105/120/150 |

200-2400mm |

0.2-6mm |

100-500kg/h |

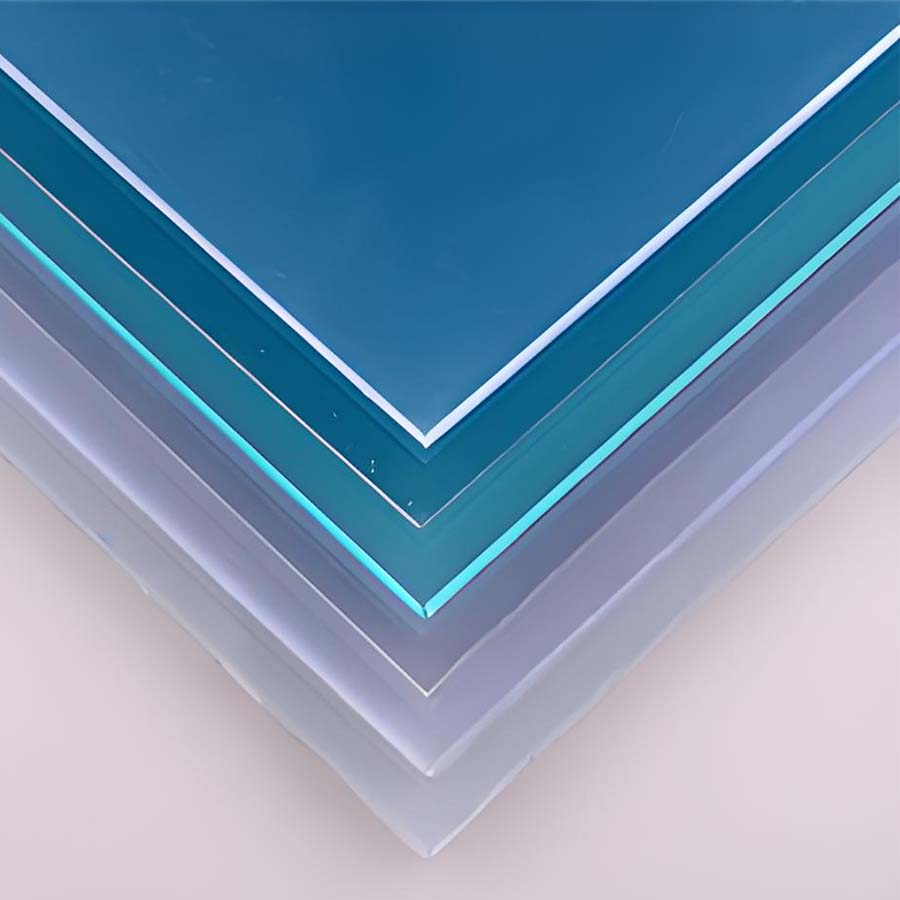

PVC extruded transparent sheets are flame retardant and self-extinguishing, high quality and low price, high transparency, good surface gloss, few crystal points, small water marks, strong impact resistance and easy to form.

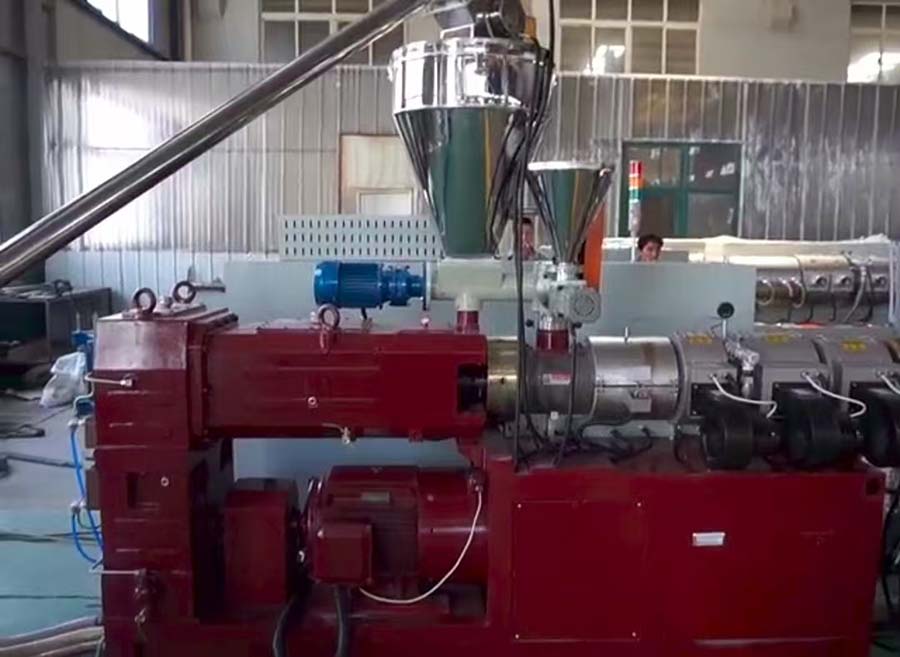

Twin-screw extruder, screen changer and hanger type mold, three-roll calender, cooling bracket, haul-off machine, cutter, winder and other auxiliary machinery.

Twin screw extruder

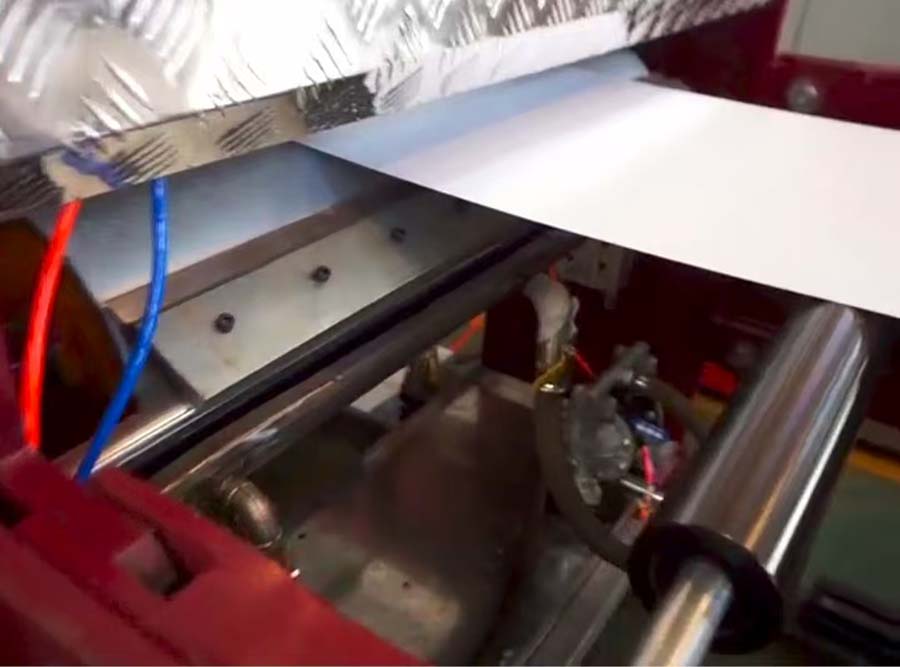

Screen changer ,hanger mold and three-roller calender

Haul-off machine

Cutter

Winding Machine

The hanger-type die head adopts a double throttling design, combined with the two-way adjustment of the pressure roller (screw + oil pressure), to achieve ±0.1mm thickness accuracy (supporting 0.2-50mm range).

The three-roll calender has independent temperature control (±1℃) to ensure uniform cooling of the sheet and avoid warping.

The heavy-duty traction machine guarantees the dimensional tolerance of the pipe/sheet (such as Dekumo equipment).

The double exhaust screw design (such as DKM-EⅡ108*36 model) effectively discharges moisture and volatiles and reduces bubble defects

The calender roller can be installed horizontally/vertically/45° tilted to meet the molding needs of sheets of different thicknesses

Free on-site installation guidance and operational training

24/7 technical support with remote assistance

Lifetime maintenance consultation

◆ Proven Technology – Over 15 years of extrusion machine manufacturing experience

◆ Cost Saving – Energy-efficient design lowers your production costs

◆ Global Service – Technicians can be sent to to your facility for on-site installation and worker training

Ruihang Plastic Machinery is a direct manufacturer of extrusion machines, based in Qingdao, China. With over 15 years of export experience, we've supplied high-quality machinery to 20+ countries worldwide.

Absolutely! Our experienced engineers can be dispatched to your facility for on-site installation and worker training. Alternatively, we offer remote online guidance for your team.

All our machines come with a 12-month warranty, and our technical team guarantees a response within 6 hours for any issues.

We provide free replacement parts (excluding wear-and-tear components) during the warranty period. For consumable parts, we charge only a minimal cost fee.

Production time varies based on specifications, but standard orders typically take 3-4 months. We'll provide a precise timeline after reviewing your requirements.

We offer live video testing before shipment, along with detailed inspection reports and videos. You're also welcome to visit our factory for on-site testing.

Definitely! We specialize in tailored solutions-just share your needs, and we'll design machinery to match your exact specifications.